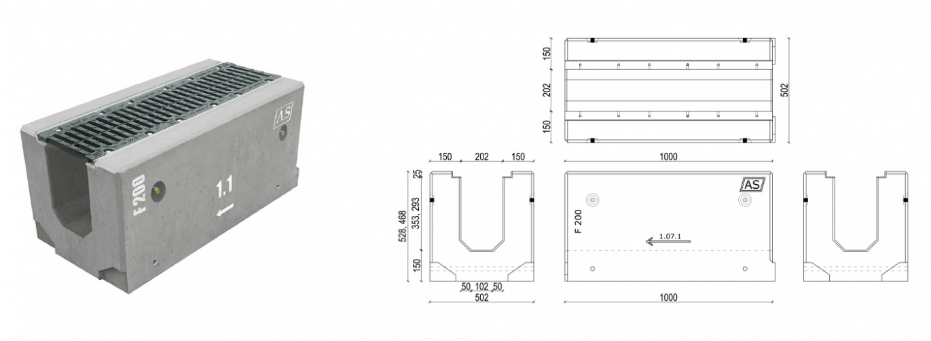

AS-200 Typ I

ODWODNIENIE ŻELBETOWE Z RUSZTEM AS-200 TYP I

Oznakowanie CE- Norma PN-EN 1433:2005

Deklaracja Właściwości Użytkowych

Atest Higieniczny B-BK-60211-0323/21

Nr Katalogowy CF

Korytka o szerokości wewnętrznej 150mm

| CF.I. | Nr elementu | KORYTKA AS-200 Typ I | Szerokość [mm] | Wysokość [mm] | Długość [mm] | Przekrój poprzeczny [cm2] | Powierzchnia wlotowa [cm2/mb] | Masa [kg] | Ruszty i pokrywy żeliwne |

|---|---|---|---|---|---|---|---|---|---|

| CF.I.1. | 1.07.1 | bez spadku | 502 | 528 | 1000 | 688 | 883 | 471 | |

| CF.I.2. | 1.1 | bez spadku | 502 | 468 | 1000 | 567 | 883 | 426 | |

| CF.I.3. | 0.1.07.1 | górny element studzienki | 502 | 528 | 1000 | 688/1172* | 883 | 424 | Kl.C250-15.6 kg |

| CF.I.4. | 0.1.1 | górny element studzienki | 502 | 468 | 1000 | 567/1172* | 883 | 378 | Kl.D400-17.4 kg |

| CF.I.5. | - | dekiel z odpływem nr 1.07.1 | 502 | 528 | - | - | - | 25 | Kl.E600-22.8 kg |

| CF.I.6. | - | dekiel z odpływem 1.1 | 502 | 468 | - | - | - | 22 | Kl.F900-26.4 kg |

| CF.I.7. | - | dekiel ślepy nr 1.07.1 | 502 | 528 | - | - | - | 22 | |

| CF.I.8. | - | dekiel ślepy nr 1.1 | 502 | 468 | - | - | - | 19 |

Elementy studzienki

Elementy studzienki

| CF.II. | Nr elementu | ELEMENTY STUDZIENKI | Szerokość [mm] | Wysokość [mm] | Długość [mm] | Masa [kg] |

|---|---|---|---|---|---|---|

| CF.II.1. | A | przelotowy bez odpływu | 382 | 440 | 780 | 212 |

| CF.II.2. | A | przelotowy z odpływem z boku | 382 | 440 | 780 | 201 |

| CF.II.3. | A | przelotowy z odpływem czołowym | 382 | 440 | 780 | 201 |

| CF.II.4. | B | z dnem; bez odpływu | 382 | 450 | 780 | 242 |

| CF.II.5. | B | z dnem; z odpływem z boku | 382 | 450 | 780 | 231 |

| CF.II.6. | B | z dnem; z odpływem czołowym | 382 | 450 | 780 | 231 |

| CF.II.7. | - | łapacz zanieczyszczeń | 180 | 250 | 400 | 3.8 |

Specyfikacja

1. Przeznaczenie - miejsce zastosowania

Zastosowanie na obszarach takich jak: powierzchnie magazynowe, drogi, ulice, parkingi, wjazdy, stacje paliw, place manewrowe, myjnie samochodowe oraz na powierzchniach narażonych na wyjątkowo silne obciążenia jak lotniska, doki przeładunkowe, bazy wojskowe itp

2. Możliwości technologiczne

- elementy bez spadku wewnętrznego,

- możliwość łączenia elementów pod kątem i połączeń kaskadowych

- studzienki z łapaczami zanieczyszczeń, dekle z króćcem, dekle zaślepiające

- korpusy z otworami w dnie lub w bocznych ściankach - do odprowadzania wody

3. Informacja techniczna

Wymiary:

- szerokość wewnętrzna: 202 mm.

- szerokość zewnętrzna: 502 mm,

- wysokość: 528, 468 mm,

- długość: 1000 mm.

Korytka żelbetowe z rusztem - "Typu I" są zbrojone i nie wymagają obetonowania bocznego, a jedynie wykonania ławy.

Odwodnienia wytworzone są z betonu polimerowo - cementowego o klasie wytrzymałości C55/67.

Materiał użyty do wykonania elementów wzmocniony jest włóknem szklanym alkalioodpornym poprawiającym w znacznym stopniu właściwości korytka na zginanie i udarność.

Beton charakteryzuje się wysoką odpornością na długotrwałe działanie mrozu oraz soli rozmrażających ("+R") oraz odpornością chemiczną w tym na substancje ropopochodne według normy PN-EN 858-1:2005.

Korpusy korytek zakończone są specjalnym wgłębieniem umożliwiającym wykonanie szczelnego połączenia elementów odwodnienia AS.

Listwy wsporcze - wykonane są z profili stalowych, gorącowalcowanych, ocynkowanych ogniowo, które są zakotwione w ściankach korpusu. Konstrukcja ta zabezpiecza krawędzie korytka i stanowi solidny element mocowania rusztów.

Ruszty - z żeliwa sferoidalnego, lakierowane lub z powłoką KTL występują w kl.C250 kN, D400 kN, E600 kN i F900 kN.

Mocowanie rusztów - wykonuje się śrubami nierdzewnymi o podwyższonej wytrzymałości, wkręcanymi w ocynkowane, gwintowane gniazda, znajdujące się w listwach wsporczych. Śruby te zapewniają blokadę przesuwu kratek, eliminację występowania luzów i "klawiszowania". Gniazda mocujące są przelotowe - przystosowane do czyszczenia.

Wbudowywanie korytek - należy wykonywać na ławie betonowej zgodnie z informacją w katalogu.

Łączenie korytek - przy zastosowaniu zapraw mrozoodpornych i wodoszczelnych.

4. Jakość, precyzja wykonania i inne

Bardzo prosty, bezpieczny w montażu i w eksploatacji wyrób od początku do końca wyprodukowany z polskich materiałów przez rodzimą firmę jest bardzo wysokiej jakości.

Najwyższą jakość produktów firma AS PPH Odwodnienia liniowe zapewnia dzięki stosowaniu "Betonu Wysokiej Wytrzymałości" oraz materiałów trwale zabezpieczonych przed korozją.

Gwarancją najwyższej jakości jest również Certyfikat ISO 9001:2008.

5. Bezpieczeństwo

Stosowanie odwodnienia AS nie stanowi zagrożenia bezpieczeństwa podczas robót montażowych, należy przy tym przestrzegać ogólnych przepisów BHP dla robót Budowlanych i Montażowych.

Odwodnienie systemem AS przy przestrzeganiu wytycznych do projektowania i instrukcji montażu, pozwoli uniknąć uciążliwych awarii i degradacji budowli, a konserwacja ograniczać się będzie do czyszczenia korytek raz w roku.