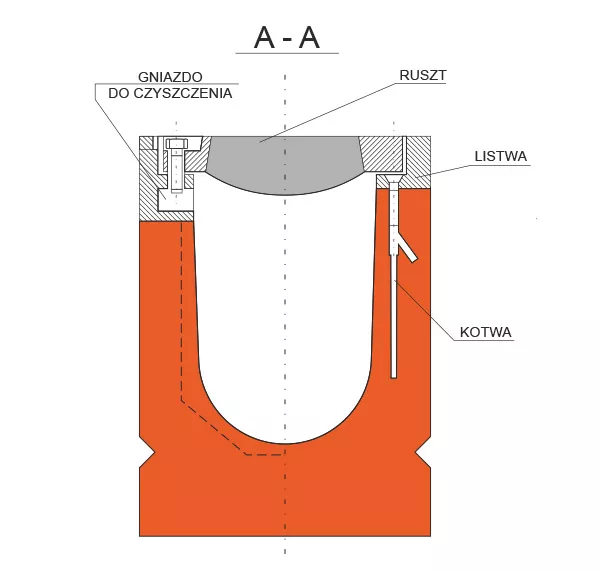

Methods fixing

With bolts positioned in the frames of the channel walls, (six bolts per running metre).

The above method of fixing meets the requirements of the harmonized standard PN-EN 1433:2005.

AS PPH basing on long term experience and tests has elaborated the grate fastening systems taking into account the safety considerations as the first factor, and then the conditions of use.

Fastening with bolts guarantees reliable co-working between the grate and the channel body, and applying bolts eliminates any clearances which occur quite frequently with other solutions leading to numerous damages to the whole drainage systems.For draining systems with a higher load class the snap systems, used by some companies do not perform well in a medium and long term of usage. Tear and wear, fatigue and corrosion of the parts lead to some clearances which expose the body walls to destructive transverse forces (vehicle braking, starting ).

The bolts used in all fastening types are made of high strength stainless steel which protects them against bolt braking or damaging. They are screwed into galvanized threaded seats equipped with cleaning canals going through. Applying stainless steel bolts efficiently protects the system against corrosion. Such a solution makes it possible to unscrew or screw the bolts with a simple tool with no difficulties. The optimal number to guarantee safety, without causing too excessive workload when using the system is six bolts per 1 m length.

AS PPH basing on long term experience and tests has elaborated the grate fastening systems taking into account the safety considerations as the first factor, and then the conditions of use.

Fastening with bolts guarantees reliable co-working between the grate and the channel body, and applying bolts eliminates any clearances which occur quite frequently with other solutions leading to numerous damages to the whole drainage systems.For draining systems with a higher load class the snap systems, used by some companies do not perform well in a medium and long term of usage. Tear and wear, fatigue and corrosion of the parts lead to some clearances which expose the body walls to destructive transverse forces (vehicle braking, starting ).

The bolts used in all fastening types are made of high strength stainless steel which protects them against bolt braking or damaging. They are screwed into galvanized threaded seats equipped with cleaning canals going through. Applying stainless steel bolts efficiently protects the system against corrosion. Such a solution makes it possible to unscrew or screw the bolts with a simple tool with no difficulties. The optimal number to guarantee safety, without causing too excessive workload when using the system is six bolts per 1 m length.